Multi-material multiphysics topology optimization

The Green Deal aims to make Europe the first climate neutral continent by 2050. The automotive and aerospace industries among others are therefore facing important challenges in terms of emission reduction. For engineers, multi-material design and topology optimization constitute modern methodologies to lightweight classical components and assembly structures.

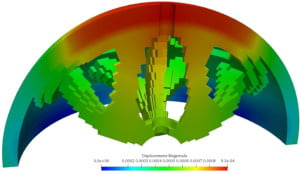

Designs generated by topolopgy optimization strategies can then easily be analyzed with the OOFELIE::Multiphysics solver itself.

The OOFELIE::Multiphysics solver includes multi-material density-based topology optimization capabilities for:

- Mechanical (reduce weight, increase stiffness)

- Thermal (maximize heat dissipation)

- Acoustical (frequencies constraints, ERP minimization)

- Compliant mechanism (to obtain force or motion transmission through elastic deformation of a flexible mechanism)

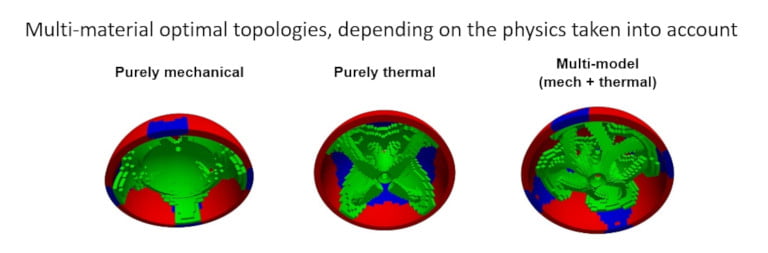

Multiphysics topology optimization

Thanks to our multi-model technology, multiple physics can be combined together in one simulation process. Typical multiphysics topology optimization can consider:

- mechanical and thermal models

- mechanical and acoustical models

- …

And our team can support you in the development of a methodology adapted to your needs.

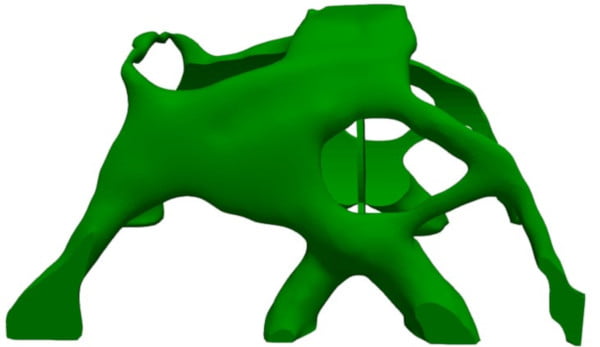

3D printing oriented

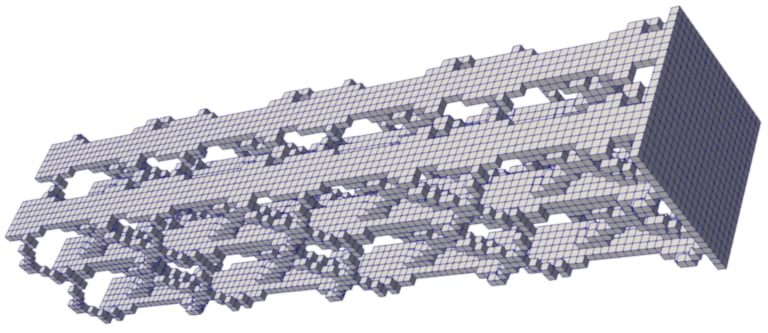

Additive Manufacturing (AM) and 3D printing provide the flexibility to produce design generated by topology optimization methodologies.

OOFELIE::Multiphysics manages AM constrains and provides smoothing capabilities to export the computed solution in STL format. Easing therefore the interoperability with 3D printers.

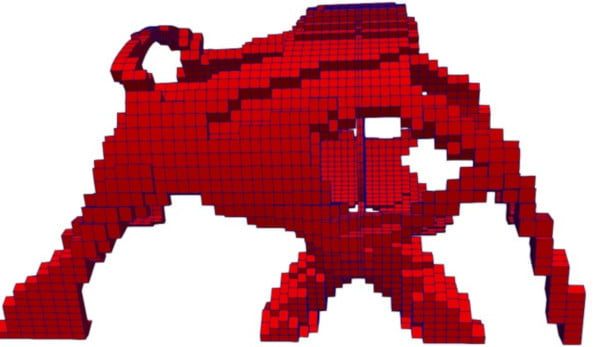

From a mesh based result …

… to a smooth CAD